CIP “Proof stamps” markings

The Commission Internationale Permanente pour l'Epreuve des Armes à Feu Portatives (Permanent International Commission for Firearms Testing - commonly abbreviated as C.I.P. or CIP) is an international organization whose members are 14 states, mainly European.

The C.I.P. safeguards that every civil firearm and all ammunition sold in C.I.P. member states are safe for the users.

To achieve this, the firearms are all professionally proofed at C.I.P. accredited Proof Houses before they can be sold to consumers. The same applies for cartridges. At regular intervals, cartridges are tested at the C.I.P. accredited Proof Houses.

History:

Firearm safety tests were made compulsory in some countries at the beginning of the 16th century. In Styria Austria by decree from Maximilian of Habsburg on the 12th of September 1501, a little later in London, and in the 17th century in Liège Belgium. At that time, proofing was executed by "proofers" at public places. All firearms of reputable brands were proofed this way. Proof testing is compulsory in Belgium since the decree of Maximilian Henry of Bavaria dated May 10, 1672. The Liège Proof House was created at this occasion. Progressively, national proof houses were set up in other countries and proof marks were introduced.

In 1914, the director of the Liège Proof House in Liège, Mr. Joseph Fraikin (director from 1908 to 1946), was the originator of the creation of the Permanent International Commission for Firearms Testing (C.I.P.).

The C.I.P. has progressively established a set of uniform rules for the proofing of firearms and ammunitions to ensure the reciprocal recognition of the proof marks of each member states.

A convention between the 13 member states was signed in 1969, ratified and converted into law in each signing state, so that the rules can be enforced to assure that every firearm and cartridge on the market has successfully passed the compulsory proofing and approval.

Proof process:

The standard proof of firearms consists of firing two overloaded cartridges producing 25% more chamber pressure than the C.I.P maximum pressure limit for the same cartridge in its commercial version. For pistol, revolver and rimfire cartridges, the standard proof is performed with overloaded cartridges that produce 30% more chamber pressure than the C.I.P maximum pressure limit for the same cartridge in its commercial version. Voluntarily testing beyond the C.I.P. maximum pressure limit is also possible for consumers who intend to use their firearms under extreme conditions (hot climates, long strings of shots, etc.). A proof mark is stamped in every successfully tested firearm. The C.I.P. does not test any further aspects regarding the correct functioning of the tested firearm. For example, aspects like the correct cycling of cartridges etc. are not part of the proofing process.

Primarily orientated towards the proof houses and manufacturers, the C.I.P. independently assesses, approves and publicizes manufacturer's data such as ammunition and chamber dimension specifications, maximum allowed chamber pressures, caliber nomenclature, etc. All this C.I.P. established data can be accessed by everyone.

Technical procedures describing how to perform proofing are also established by the C.I.P. and updates to the various test methods are issued in the form of "decisions". These decisions can also easily be obtained by everyone involved.

The C.I.P. formally distributes established data and decisions to the member states through diplomatic channels for publishing in their official journals. After official publication C.I.P. established data and decisions obtain(s) indisputable legal status in all C.I.P. member states.

Governmental organizations, like military and police forces and other firearms bearing public power agencies, from the C.I.P. member states are legally exempted from having to comply with C.I.P. rulings. This does not automatically imply that all firearms and ammunitions used by governmental organizations in C.I.P. member states are not C.I.P. compliant, since those organizations often choose to self-impose the relevant C.I.P. standards for their service firearms and ammunition.

Firearms proofing Sample of proof marks

Small arms manufacturers and importers within the C.I.P. member countries are obliged to request one of the accredited Proof Houses to perform the proofing of all arms they manufacture or import. No small arm can be put on the market in any of the C.I.P. member states without prior successful proofing in an accredited proof house according to the C.I.P. decisions.

After the proof test and if successful, two or three proof marks are always applied to the main (highly stressed) parts of the arm, namely the barrel, the chamber (when not part of the barrel) and the locking mechanism. A serial number indicating the year of proofing is also marked on these parts. In case a firearm was voluntary successfully tested at a higher than the normally required proof-test pressure superior proof marks are applied on the relevant parts.

Only after that, the arm is released to the manufacturer or importer who can sell it or deliver it, if already sold.

Sample(s) of proof marks

To the right is an example of Austria proof marks.

The NPv marked here with (1) in the picture

stands for Nitrium powder. There is also

black powder proof mark which then has the marking

NSv for “Schwarz Pulver”. The Austrian Eagle

marked with (2) shows that this barrel was test

fired in Austria and under Austrian standards.

The “EWW” shows the month and year this barrel

was proof shot. Below is a list which shows the

combination of how the letters are coded.

The month coding started in 2001.

Month codes

E=January L=February N=March B=April

S=May Z=June G=July P=August I=September

C=October V=November A=December.

Year codes

W=1 K=2 R=3 F=4 M=5 H=6 Y=7 T=8 D=9 O=0

In the case of this barrel in the picture the proof shot

date is January of 2011.

Below you have the German proof stamp. Here again you have first the German Eagle to show this barrel was proof shot by German standards. The “N” under the eagle shows it was proof shot to Nitrium powder standards. In Germany there is a standard for black powder and in this case the eagle sits on a “S” for “Schwarzpulver”.

The “BA” is the date stamp. A=0 B=1 C=2 D=3 E=4 F=5 G=6 H=7 I=8 K=9. This this proof stamp is from 2010. The sign to the right of the BA is where the barrel was proof shoot. In this example it is Ulm.

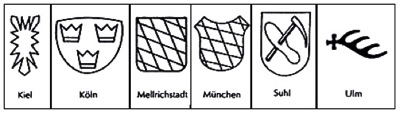

At this time there are five “Beschussämter” in Germany. They are in Kiel, Köln (Cologne) Mellrighstadt, München (Munich), Shul and Ulm. Below you see how each of these places use their sign. In the US you will find the Kiel stamp on the German made SIG Sauer pistols and the Ulm on HK and Walther pistols.

Is testing today really necessary?

In the US manufactures do not need proof shot their guns by a government or independent institution. Most people would think with modern manufacturing this would not be necessary. Below you will see a picture of a .223 proof shot shell. You will notice a ring on the wall marked with a white arrow.

I got this from Germany, where I sold years ago a US manufactured rifle and it was proof shot. The US manufacturer sold this rifle with a chamber which was cut into; a dangerous defect their QC did not see.

A clear manufacturing defect which on the fair side can only be found by proof shooting the rifle. Who ever cleared this rifle for sale did not inspect the brass carefully.

So when ever you shoot your guns, check your brass afterwards. It might tell you important things about your firearm.

MDW Guns is not associated nor represent any of the here listed companies.

The names of other companies, products and services are the property of their respective owners.

© MDW Guns 2003-2025 • Tel: 207 583-8296 or 603 491-1469 • sales@mdwguns.com

388 Deer Hill Rd. • Waterford, ME 04088 • USA